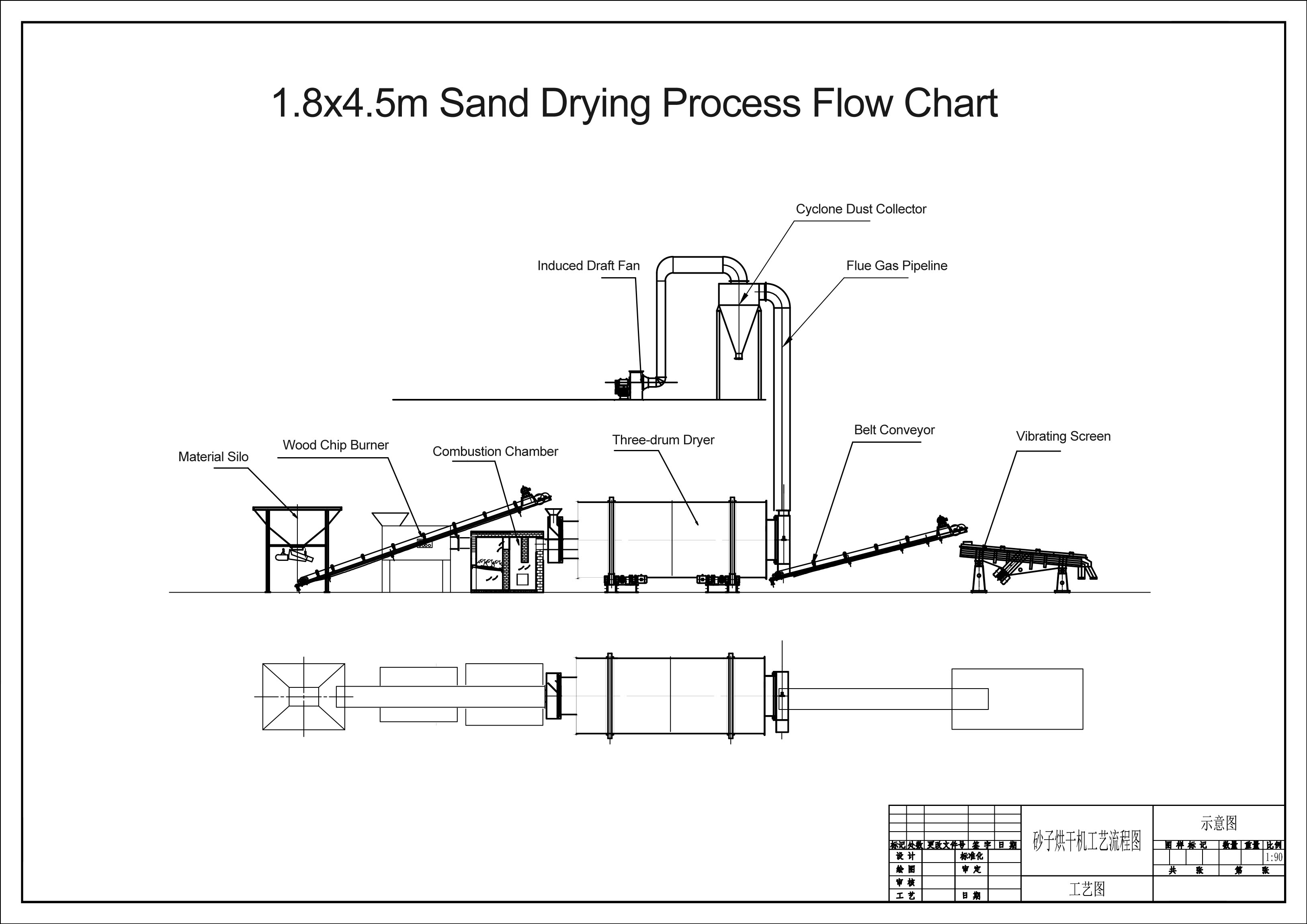

The Senta sand drying production line adopts an integrated control cabinet, which is easy to operate and can be controlled to start and stop with just one button. The heat source can be provided by various materials such as diesel, natural gas, biomass pellets, wood, and coal. The sand is evenly fed into the dryer from the hopper and moves back and forth three times inside the dryer. The sanding plate inside the cylinder enables the sand to fully come into contact with the hot air, achieving thorough drying. Finally, the finished product is sent out through the discharge port. The exhaust gas is sent through the pipeline into the dust collector for treatment, effectively reducing environmental pollution.

Incluing equipment:

Biomass pellet burner

Combustion chamber

Cyclone dust collector

Conveyor belt machine

Draw fan